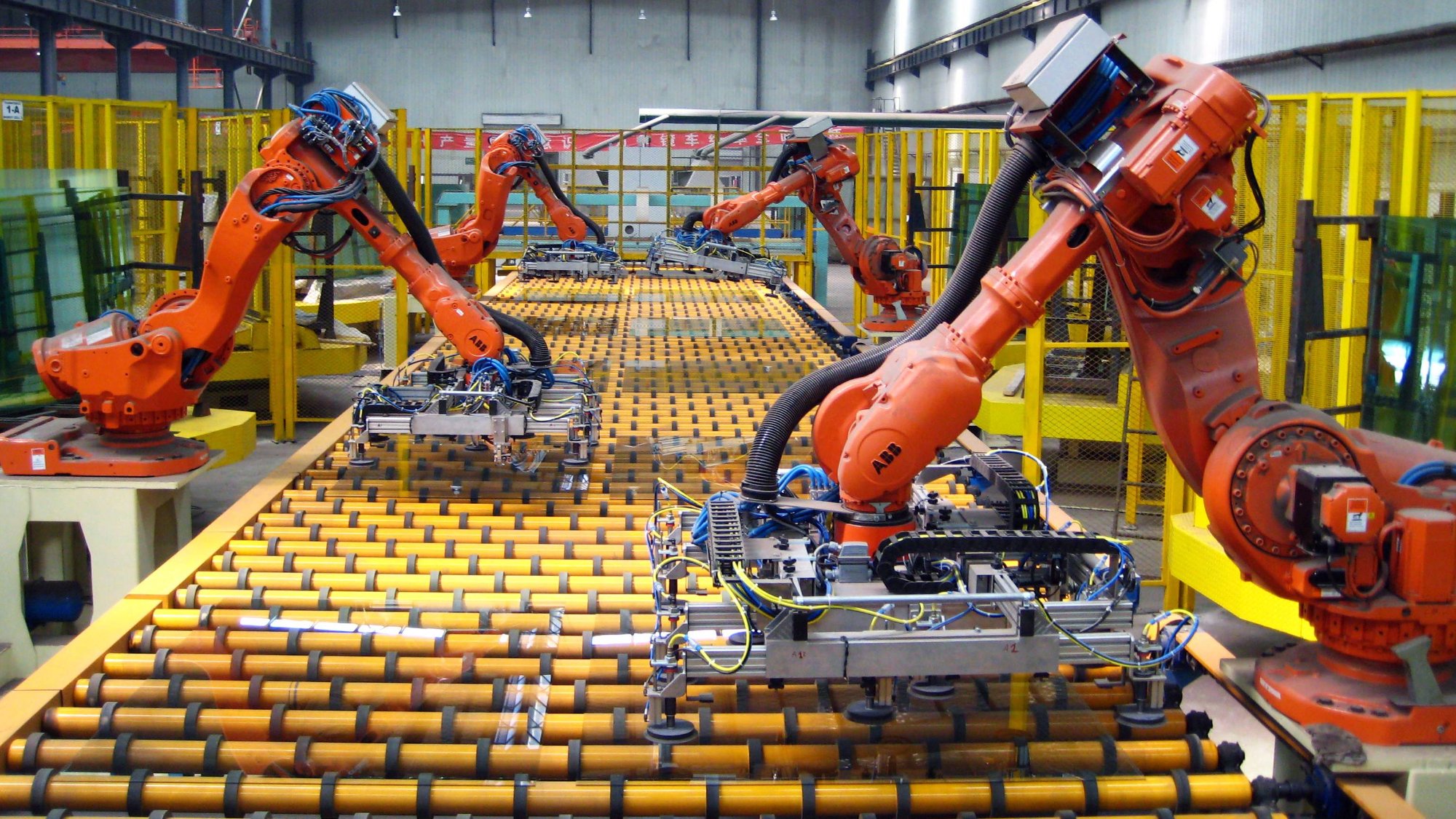

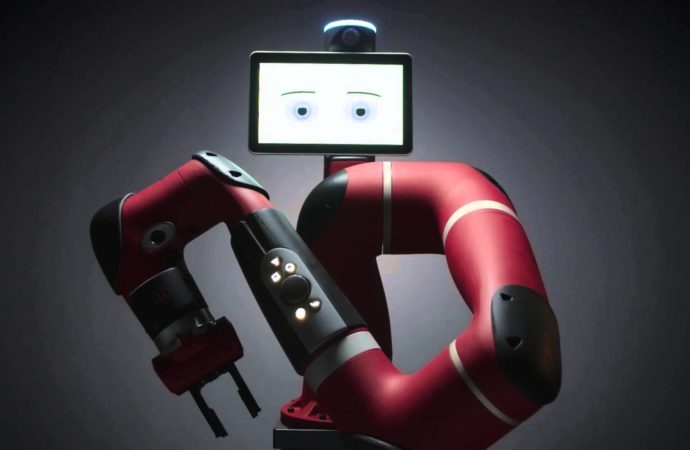

Industrial robot

Industrial robot as defined by ISO 8373:2012: An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications Classification by mechanical structure The number of axles should be considered as the basic characteristic supplied by the manufacturer and not as axes added later by the user. The robots are mechanically broken down into the following main types: Descartes robot, SCARA robot, articulated robot arms (usually 6 axes), parallel robot, cylindrical robot Typical applications for industrial robots in industrial applications include welding, painting, deburring, assembly, pick and place, palletising, product verification and testing, etc. all of which can only be achieved with high endurance, speed and accuracy. The most commonly used robotics for industrial automation include articulated robots, SCARA robots, and mobile robots.